Version 2

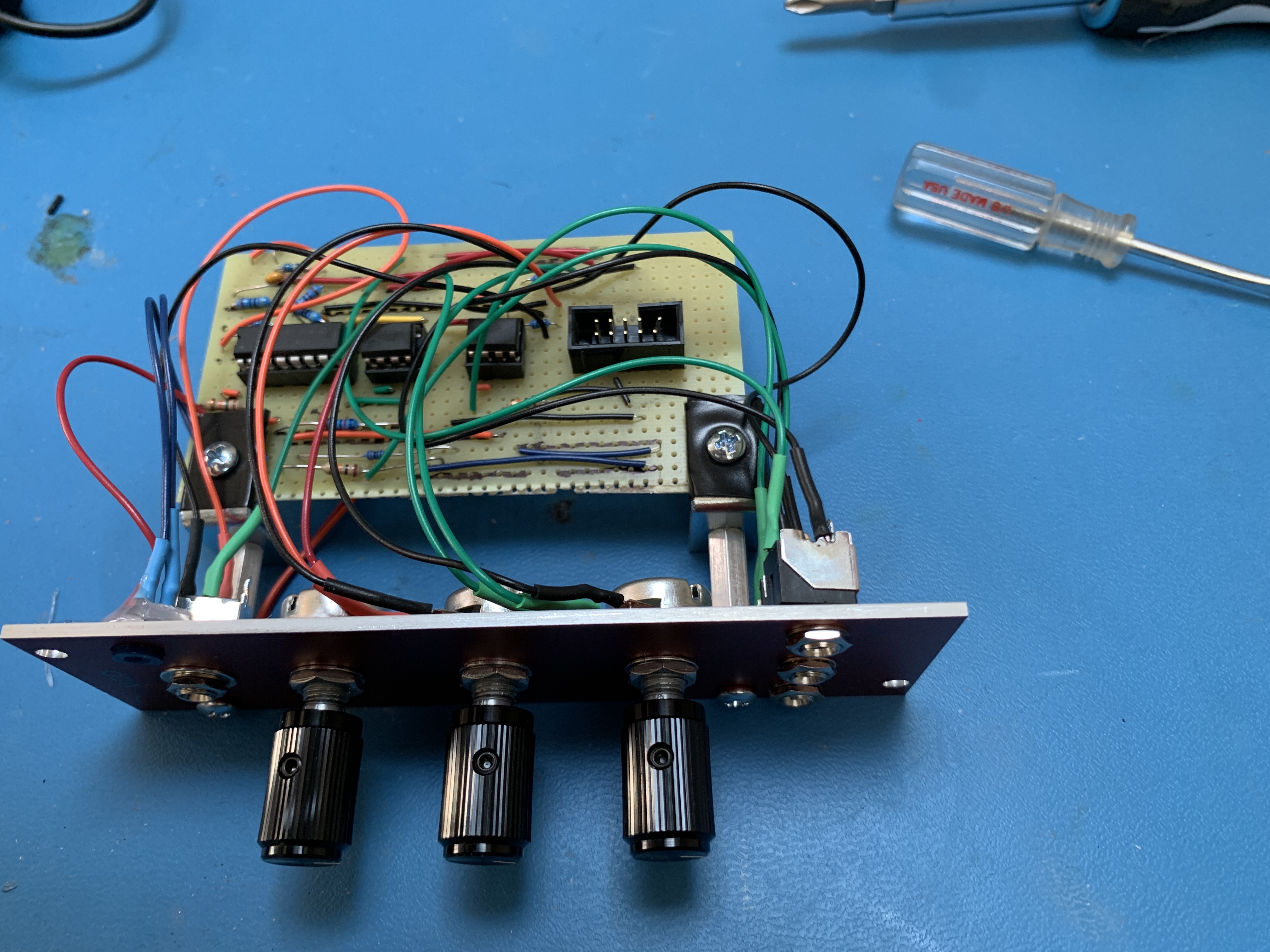

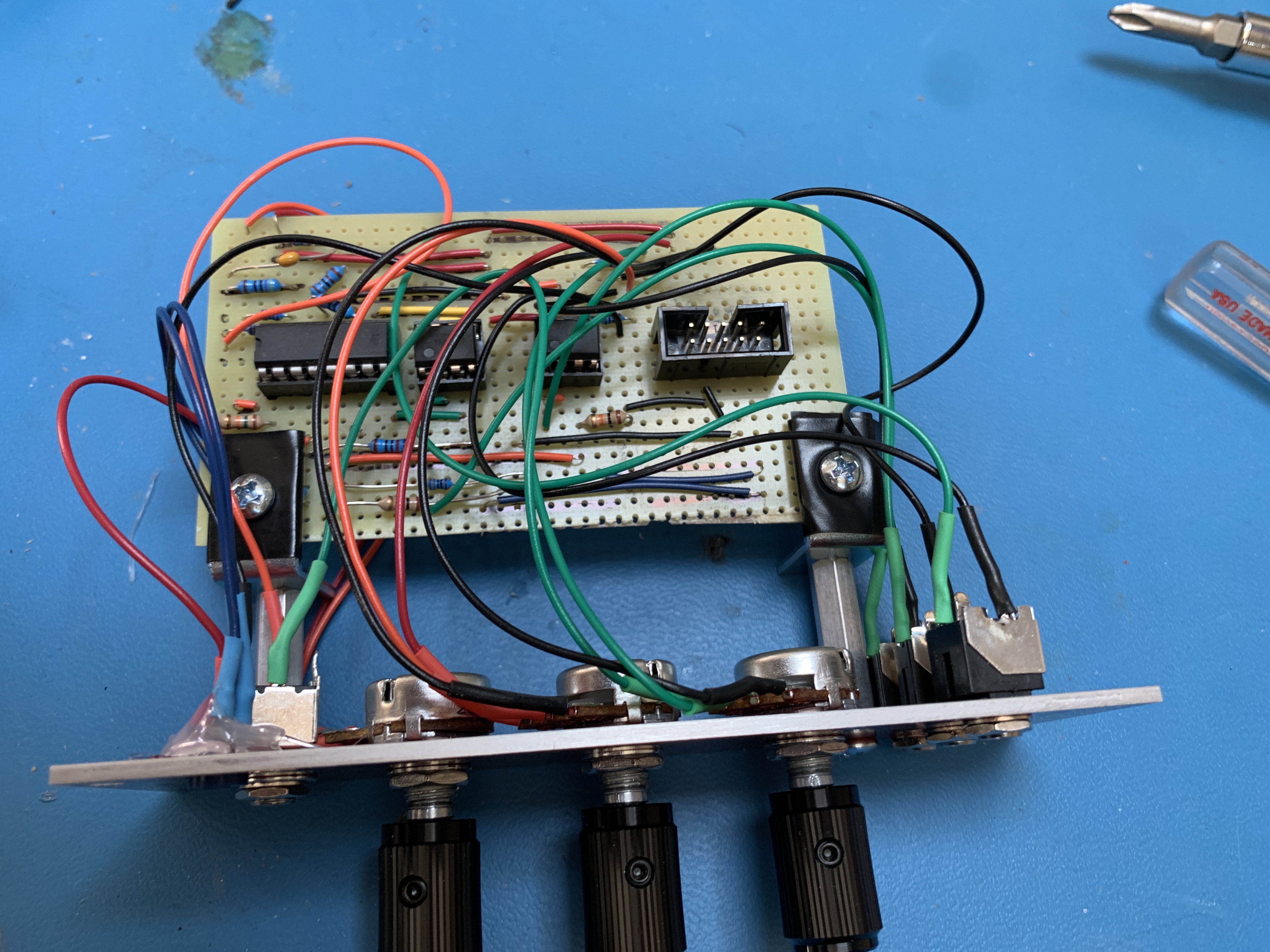

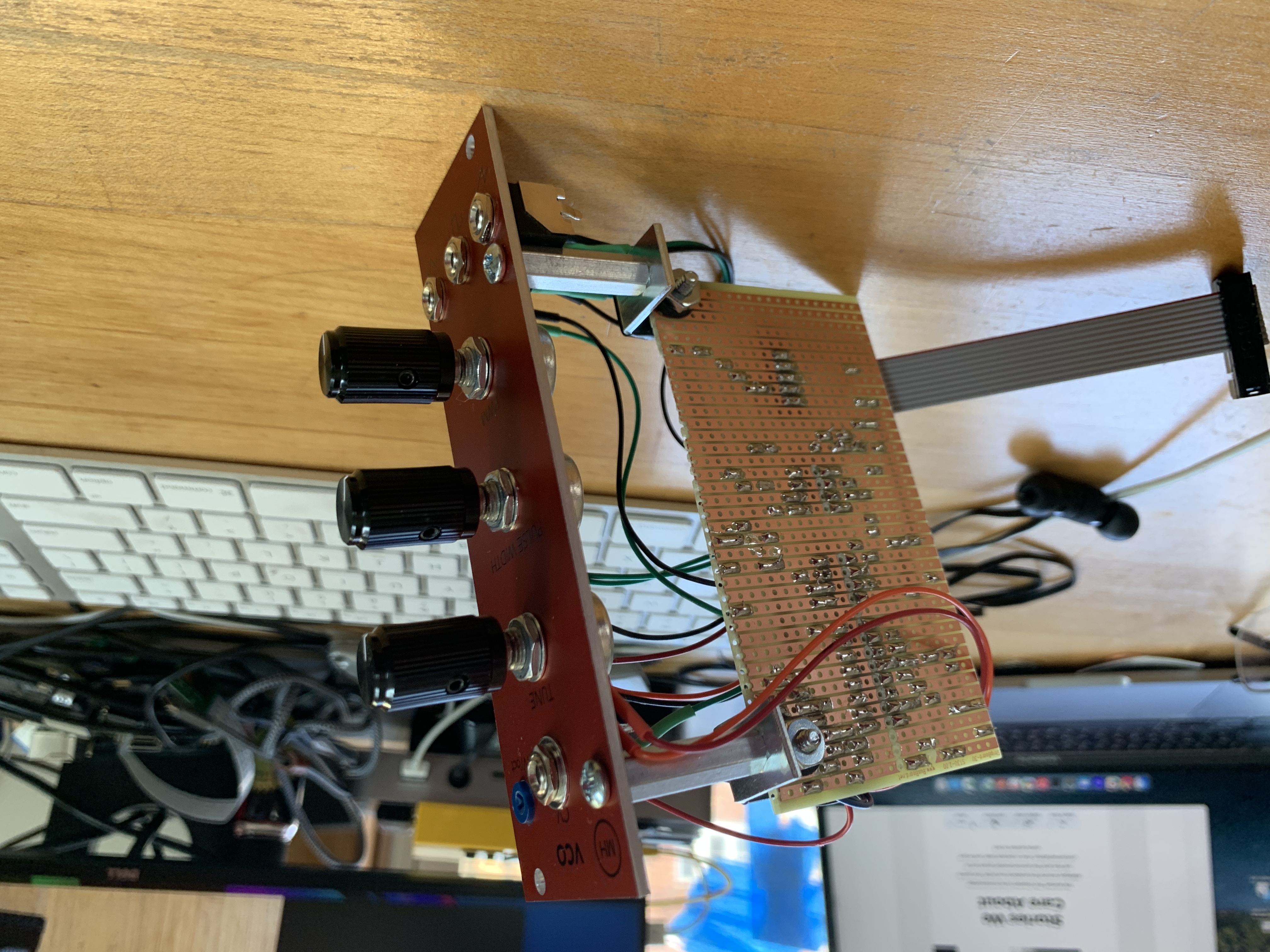

For practice and to get better, I made another voltage controlled oscillator. This time, I also ordered a custom front panel that I designed. The front panel ended up costing me around $55, so it’s by far the most expensive part of this project. It’s also something that I doubt I do again, but it was way fun to figure out how to do it.

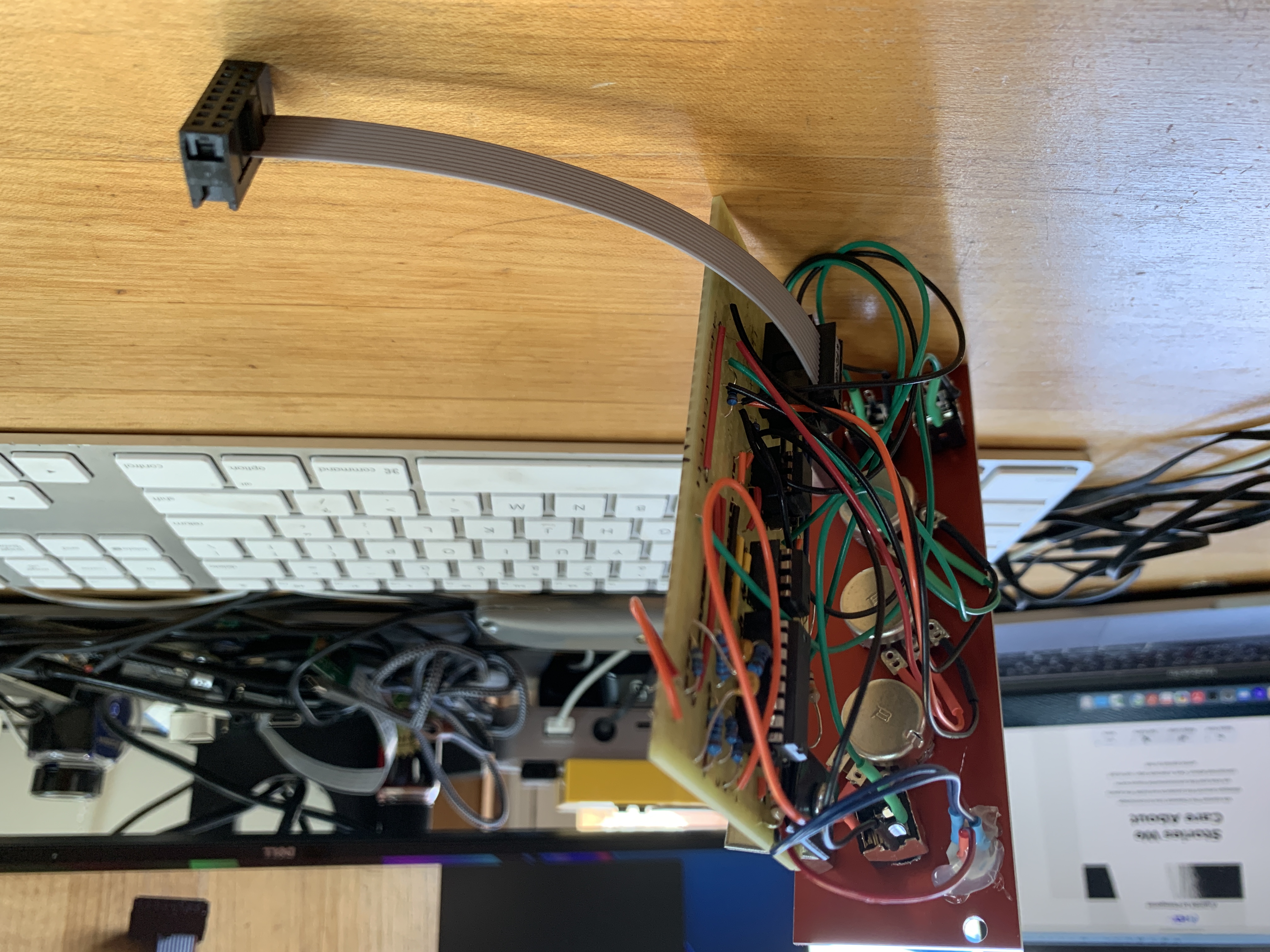

Looking at the final product, I still see a ton of flaws. But overall I’m pleased with it. After assembling everything I did test it again, just to make sure I didn’t break anything. I still get sound out of it. I don’t have a second module to use for control voltage, so I haven’t tested that. But I think it should work. Today I just put together a cable and I hope I did it the right way. My brother will have to test it when I give it to him.

The first mistake I made was I missed one hole that needed to be drilled in the panel. My second mistake was drilling the hole too big. Stupidly, I drilled for the washer size and not the size I needed for the jack. Fortunately, a bigger washer from a potentiometer fixed that.

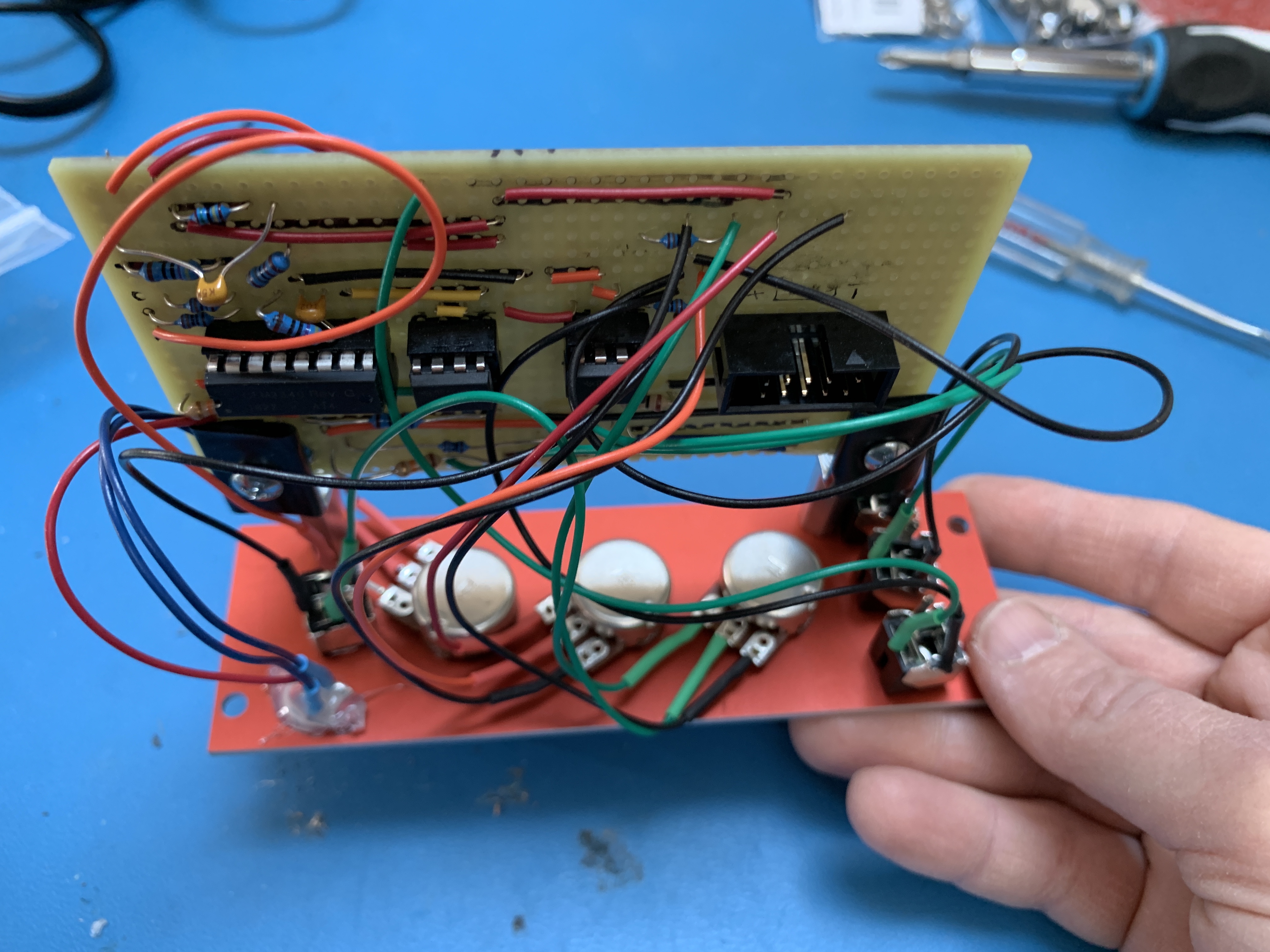

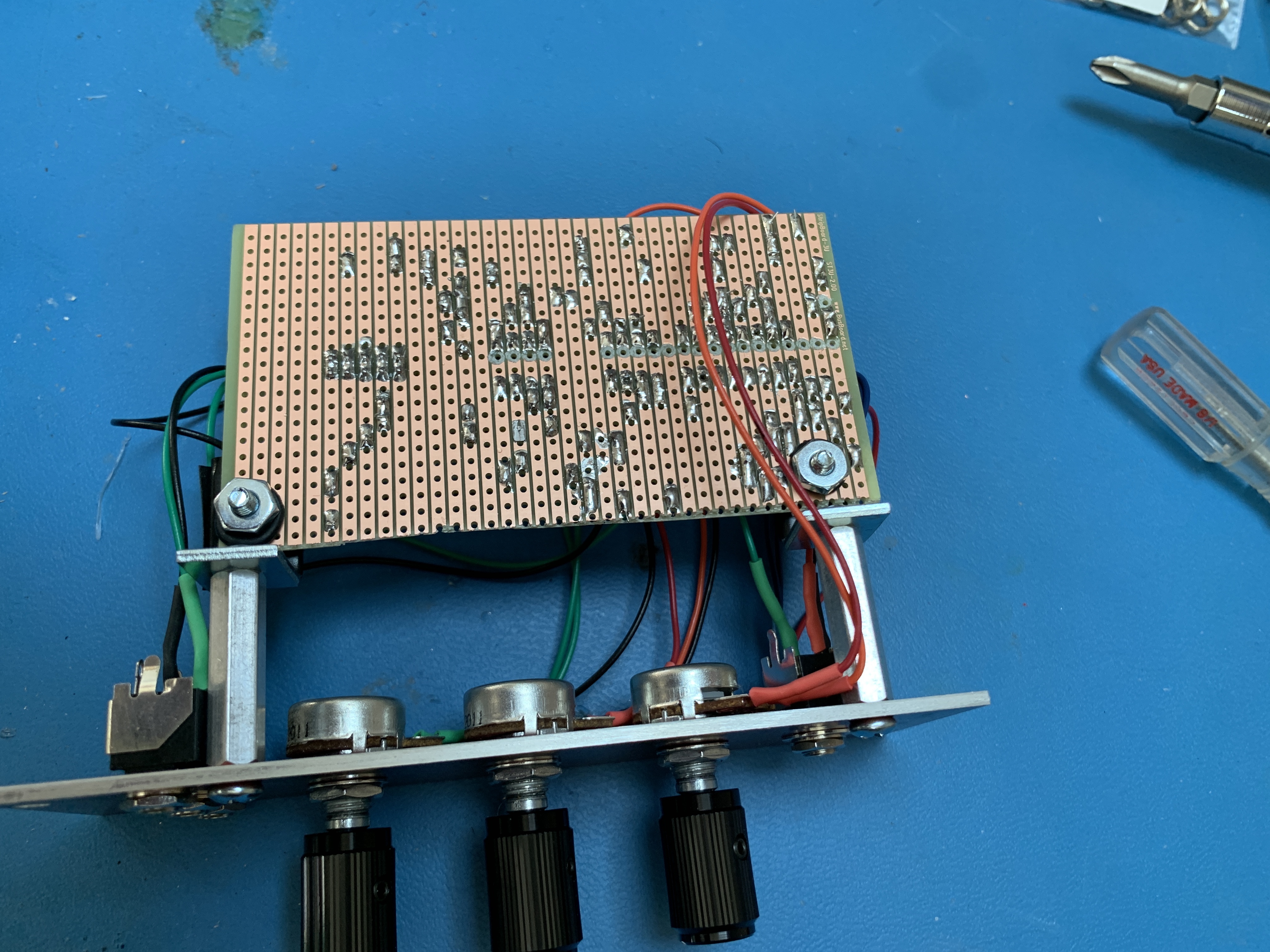

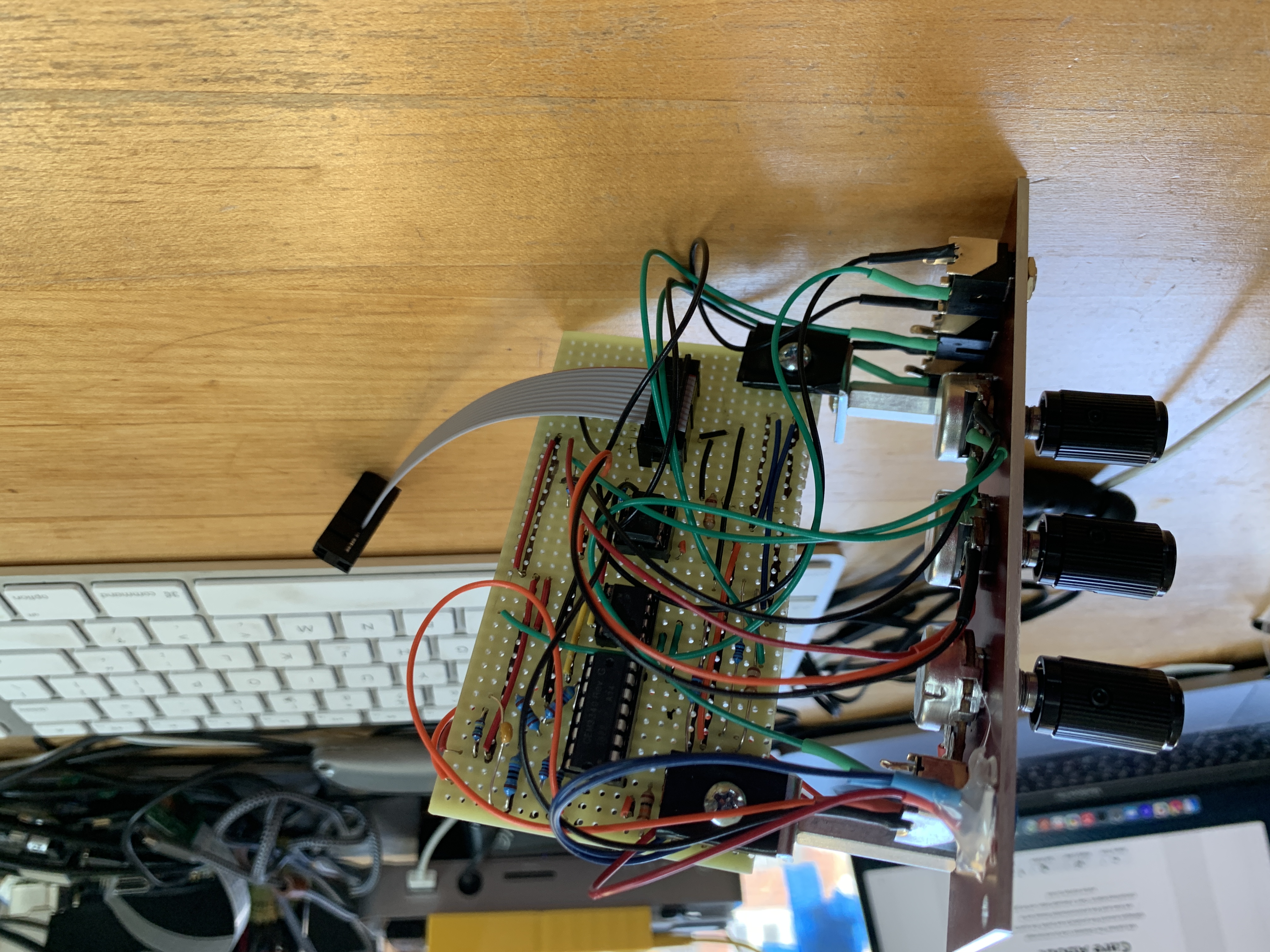

Here are some more pictures of the rest of the project.

And here’s a short movie showing how it all sounds.